Ho na le mefuta e meraro ea likhalase tse bataletseng lefatšeng kajeno: ho taka sephara, mokhoa oa float le calendering. Khalase e phaphametseng, e etsang karolo e fetang 90% ea kakaretso ea tlhahiso ea likhalase ha joale, ke lisebelisoa tsa motheo tsa kaho ea likhalase tsa meralo ea lefatše. Ts'ebetso ea tlhahiso ea likhalase tsa Float e thehiloe ka 1952, e behileng maemo a lefats'e a tlhahiso ea likhalase tsa boleng bo holimo. Ts'ebetso ea khalase e phaphametseng e kenyelletsa mehato e mehlano ea mantlha:

● metsoako

● ho qhibiliha

● ho theha le ho roala

● annealing

● ho seha le ho paka

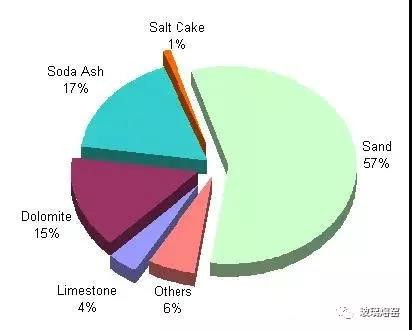

Lisebelisoa

Batching ke mohato oa pele, o lokisang lisebelisoa tse tala bakeng sa ho qhibiliha. Lisebelisoa tse tala li kenyelletsa lehlabathe, dolomite, limestone, soda ash le mirabilite, tse tsamaisoang ka teraka kapa terene. Lisebelisoa tsena tse tala li bolokiloe ka kamoreng ea ho hlapela. Ho na le li-silos, li-hoppers, mabanta a li-conveyor, li-chute, ba bokellang lerōle le mekhoa e hlokahalang ea ho laola ka kamoreng ea thepa, e laolang ho tsamaisa thepa e tala le ho kopanya lisebelisoa tsa batch. Ho tloha ha lihlahisoa tse tala li isoa kamoreng ea thepa, li lula li falla.

Ka har'a kamore ea ho hlapela, lebanta le lelelele le sephara la conveyor le tsoela pele ho tsamaisa thepa e tala ho tloha lisilaneng tsa lisebelisoa tse tala ho ea mokatong oa lifti ea libakete ka lera ka tatellano, ebe le li romella sesebelisoa sa boima ho lekola boima ba tsona bo kopaneng. Likaroloana tsa khalase tse tsosolositsoeng kapa li-recycle line line li tla ekeletsoa metsoakong ena. Sehlopha se seng le se seng se na le likhalase tse ka bang 10-30% tse robehileng. Lisebelisoa tse omeletseng li kenngoa ka har'a motsoako ebe li kopantsoe ka har'a batch. Sehlopha se tsoakiloeng se romelloa ho tloha kamoreng ea ho kopanya ho ea silo ea hlooho ea sebōpi bakeng sa polokelo ka lebanta la conveyor, ebe e kenngoa ka sebōping ka tekanyo e laoloang ke sefepi.

Sebopeho se Tloaelehileng sa Khalase

Cullet Yard

Fepa Lisebelisuoa Tse Kopantsoeng ka Sekoting sa Sebopi ho fihlela ho likhato tse 1650 ka Hopper.

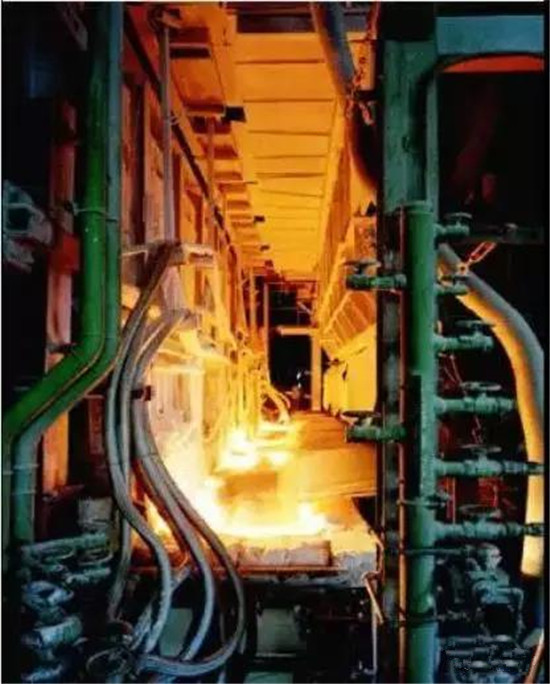

Ho qhibiliha

Sebōpi se tloaelehileng ke sebōpi sa lelakabe se pota-potileng se nang le li-regenerator tse tšeletseng, bophara ba limithara tse 25 le bophara ba limithara tse 62, se nang le matla a letsatsi le letsatsi a tlhahiso ea lithane tse 500. Likarolo tse ka sehloohong tsa sebōpi ke letamo le qhibilihisang / clarifier, letamo la ho sebetsa, regenerator le sebōpi se senyenyane. Joalokaha ho bontšitsoe setšoantšong sa 4, e entsoe ka thepa e khethehileng ea ho hanyetsa 'me e na le mohaho oa tšepe holim'a foreimi e ka ntle. Beche e romelloa letamong la sebopi ka sephepelo, 'me letamo le qhibilihang le futhumatsoa ho 1650 ℃ ke sethunya sa setlolo sa khase ea tlhaho.

Khalase e qhibilihisitsoeng e phalla ho tloha letamong la ho qhibiliha ho ea sebakeng sa molala ka ho hlakisa 'me e tsosoa ka ho lekana. Ebe e phalla karolong e sebetsang 'me butle-butle e pholile ho fihlela ho likhato tse ka bang 1100 ho etsa hore e fihle ho viscosity e nepahetseng pele e fihla bateng ea tin.

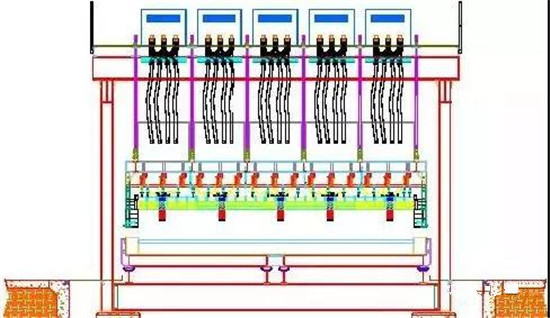

Ho theha le ho Coating

Mokhoa oa ho etsa khalase ea metsi e hlakileng ka har'a poleiti ea khalase ke mokhoa oa ho qhekella ka mechine ho latela mokhoa oa tlhaho oa thepa, 'me botenya ba tlhaho ba thepa ena ke 6.88 mm. Khalase ea metsi e phalla ka ntle ho sebōpi ka sebaka sa mocha, 'me phallo ea eona e laoloa ke lemati le feto-fetohang le bitsoang pheleu, e ka bang ± 0.15 mm ka hare ho khalase ea metsi. E phaphamala holim'a thini e qhibilihisitsoeng - ke kahoo lebitso la khalase ea float. Khalase le thini ha li sebetsane 'me li ka aroloa; Ho hanyetsa ha bona ka mokhoa oa limolek'hule ho etsa hore khalase e be boreleli.

Bate ke yuniti e tiisitsoeng moeeng o laoloang oa nitrogen le hydrogen. E kenyeletsa ho tšehetsa tšepe, likhetla tse ka holimo le tse ka tlaase, li-refractories, thini le lisebelisoa tsa ho futhumatsa, ho fokotsa sepakapaka, lisebelisoa tsa mocheso, tsamaiso ea tsamaiso ea k'homphieutha, hoo e ka bang limithara tse 8 ka bophara le bolelele ba limithara tse 60, le lebelo la tlhahiso le ka fihla ho limithara tse 25 / motsotso. Bate ea masenke e na le lithane tse ka bang 200 tsa thini e hloekileng, e nang le mocheso o tloaelehileng oa 800 ℃. Ha khalase e etsa lesela le tšesaane qetellong ea sekoti sa ho hlapa ka thini, se bitsoa poleiti ea khalase, 'me letoto la li-drawer tse khonang ho fetoha li sebetsa mahlakoreng ka bobeli. Opereishene e sebelisa lenaneo la taolo ho beha lebelo la sebōpi le mochini oa ho taka. Botenya ba poleiti ea khalase bo ka ba pakeng tsa 0.55 le 25 mm. Karolo e ka holimo ea ho futhumatsa e sebelisoa ho laola mocheso oa khalase. Ha poleiti ea khalase e ntse e phalla ka har'a bateng ea thini, mocheso oa poleiti ea khalase o tla theoha butle-butle, ho etsa hore khalase e batalle 'me e bape. Nakong ena, acuracoat e ka sebelisoa ® On line plating ea filimi e bonahatsang, filimi e tlaase ea e, filimi ea ho laola letsatsi, filimi ea photovoltaic le filimi ea ho itlhoekisa ka thepa ea pyrolysis CVD. Ka nako ena, khalase e se e loketse ho pholile.

Bath Cross Section

Khalase e Hasoa ka Lera e tšesaane holim'a thini e qhibilihisitsoeng, e bolokiloe e arohane le thini, 'me e entsoe ka poleiti.

Karolo ea ho futhumatsa e leketlileng e fana ka phepelo ea mocheso, 'me bophara le botenya ba khalase bo laoloa ke lebelo le angle ea motsu oa bohale.

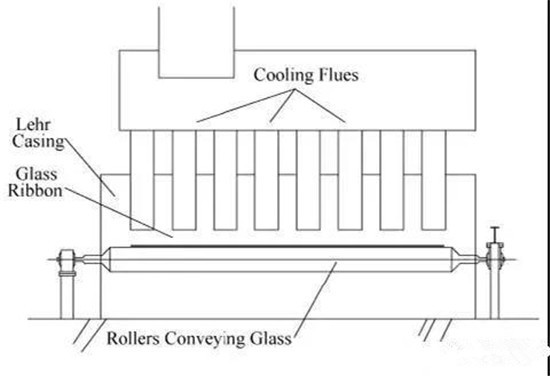

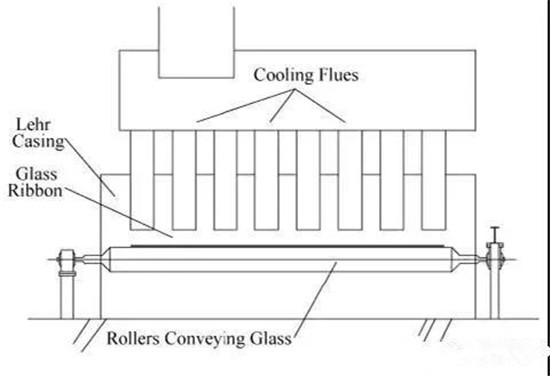

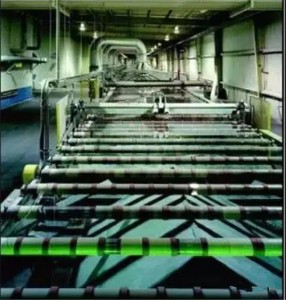

Annealing

Ha khalase e entsoeng e tloha ka bateng ea thini, mocheso oa khalase ke 600 ℃. Haeba khalase ea khalase e pholile sepakapakeng, bokaholimo ba khalase bo tla pholile ka potlako ho feta bokahare ba khalase, e leng se tla baka khatello e tebileng ea bokaholimo le khatello e kotsi ea kahare ea khalase.

Karolo ea Annealing Kiln

Mokhoa oa ho futhumatsa oa khalase pele le ka mor'a ho bōptjoa hape ke mokhoa oa ho theha khatello ea kelello ka hare. Ka hona, hoa hlokahala ho laola mocheso ho fokotsa butle-butle mocheso oa khalase ho mocheso o potolohileng, ke hore, annealing. Ha e le hantle, ho annealing ho etsoa ka sebōpi se seng se behiloe sa mocheso oa "gradient annealing" (sheba setšoantšo sa 7) bophara ba limithara tse 6 le bolelele ba limithara tse 120. Sebōpi sa annealing se kenyelletsa lintho tse futhumatsang tse laoloang ka motlakase le li-fan ho boloka mocheso o fapaneng oa lipoleiti tsa khalase o tsitsitse.

Sephetho sa ts'ebetso ea annealing ke hore khalase e pholile ka hloko mocheso oa kamore ntle le khatello ea nakoana kapa khatello ea maikutlo.

Ho Seha le ho Paka

Lipoleiti tsa likhalase tse pholileng ke sebōpi sa annealing li isoa sebakeng sa ho itšeha ka tafole ea rolara e kopantsoeng le tsamaiso ea ho khanna ea sebōpi sa annealing. Khalase e fetisa mokhoa oa ho hlahloba marang-rang ho felisa bofokoli leha e le bofe, 'me e khaoloa ka lebili la daemane ho tlosa moeli oa khalase (thepa e bohale e sebelisoa hape e le khalase e robehileng). Ebe u e khaola ka boholo bo hlokoang ke moreki. Bokaholimo ba khalase bo fafatsoa ka phofo, e le hore lipoleiti tsa khalase li ka phutheloa le ho bolokoa ho qoba ho khomarelana kapa ho ngoapa. Ka mor'a moo, lipoleiti tsa khalase tse se nang sekoli li aroloa ka mekotla bakeng sa ho paka ka mechine ea matsoho kapa ea othomathiki, ebe e fetisetsoa sebakeng sa polokelo bakeng sa polokelo kapa ho romelloa ho bareki.

Ka mor'a hore Glass Plate e Tlohe Sebōping sa Annealing, Plate ea Khalase e Thehiloe ka ho Fetisisa 'me e Isoa Sebakeng sa Pholiso ho Tsoela Pele ho Fokotsa Mocheso.